Law of Laplace

Module: tutorials.04_EM_tissue.02_laplace.run

Section author: Matthias Gsell <matthias.gsell@medunigraz.at>

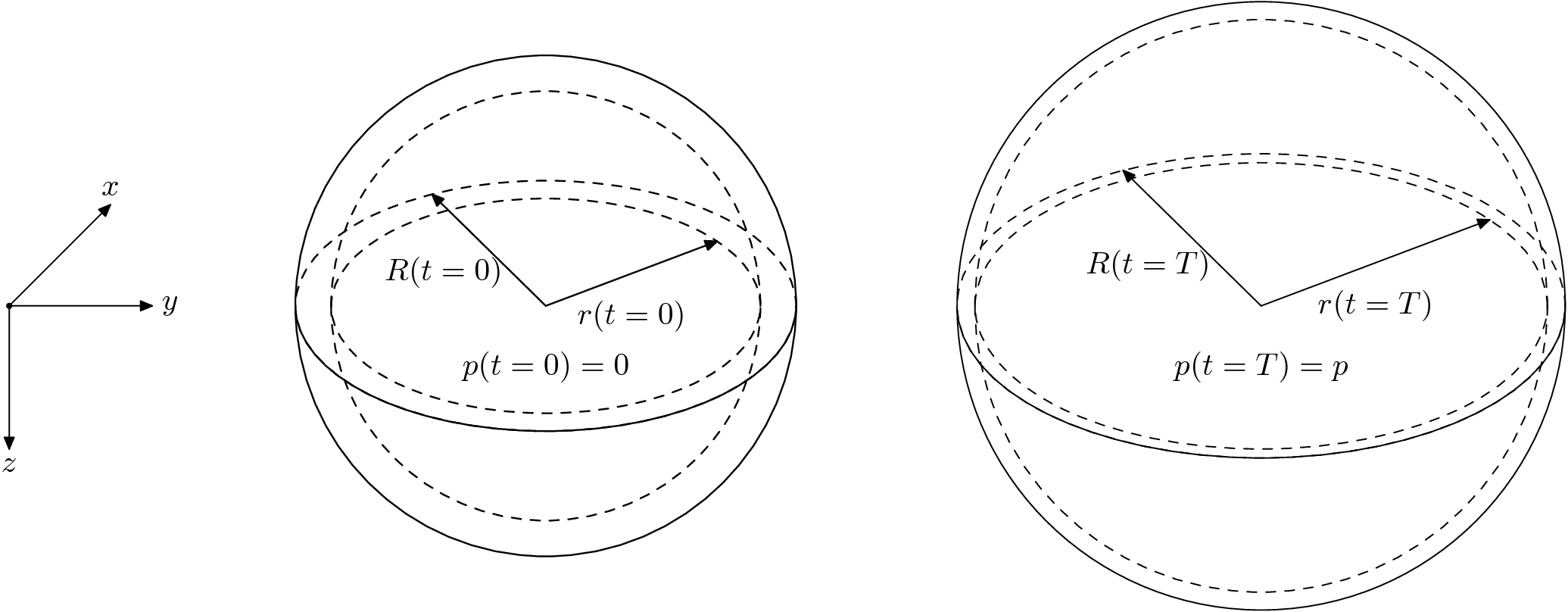

This example verifies the computed stress and the computed work using a simple spherical shell geometry and time-varying Neumann boundary condition applied on the inner boundary. To verify the computed stress, we use the law of Laplace, see [2], to estimate the wall stress and compare it against the mean computed stress. For the work varification, we compute the external work analytically and compare it against the computed internal work.

Stress Verification

To verify the stress, we use the law of Laplace to estimate the wall stress (wall tension).The

law of Laplace can be used to describe

the wall stress of a spherical shell in terms of the surface pressure applied on the inner boundary,

see Figure Fig. 132. To estimate the wall tension, we consider the geometry

at time  with pressure

with pressure  and radii

and radii  .

.

Derivation Of Laplace’s Law

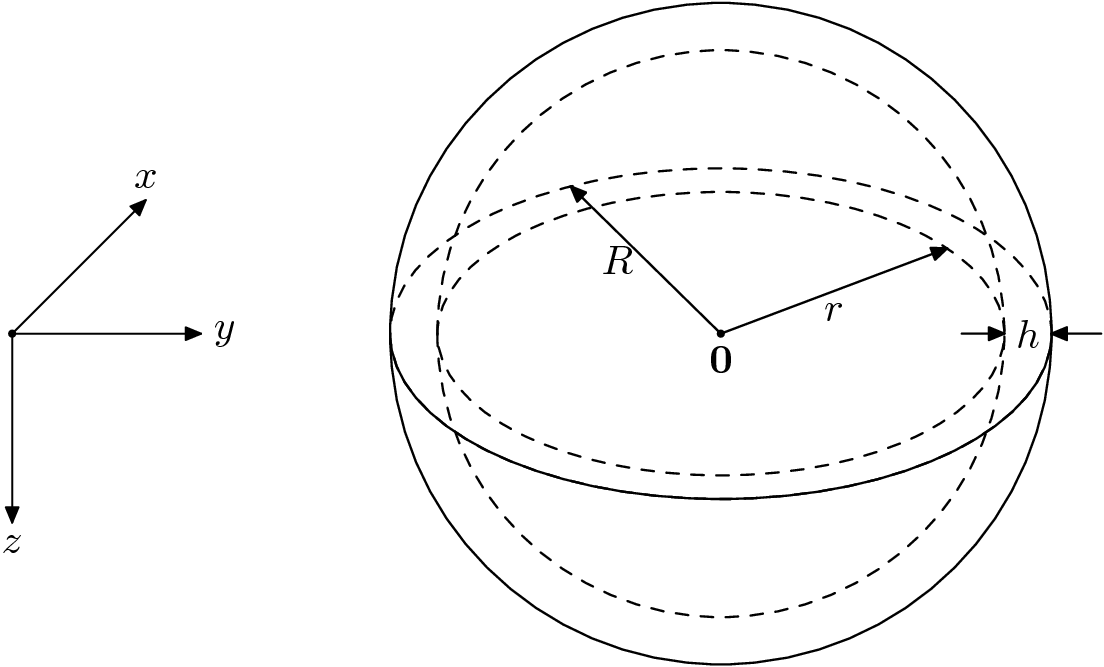

To derive Laplace’s law we want to use the balance of forces. We assume that the center of the spherical shell

is the origin and we denote the inner radius of the deformed geometry by  and the outer radius by

and the outer radius by

with

with  , see figure Fig. 133.

, see figure Fig. 133.

By  we denote the wall thickness which is given by

we denote the wall thickness which is given by  . Next, we clip the geometry using the x-y-plane

as a clipping plane and obtain two equally sized shells, see figure Fig. 134.

. Next, we clip the geometry using the x-y-plane

as a clipping plane and obtain two equally sized shells, see figure Fig. 134.

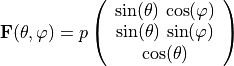

The force vector acting on the inner surface is given in spherical coordinates by

with ![\theta \in [0, \pi]](../../_images/math/d8fe4fa46b55d9ad117554e6bbafe71d7cd45f12.png) and

and ![\varphi \in [0, 2 \pi]](../../_images/math/60ff373055372c64ba28acaadb86a826aaee51c5.png) . The components of the total force vector

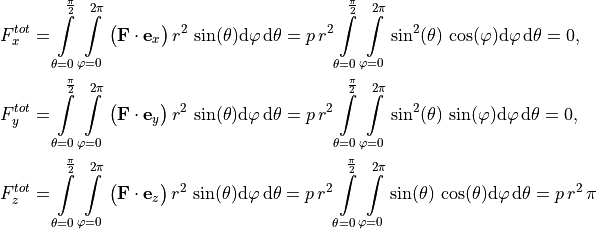

. The components of the total force vector  are

are

(41)

with  since we only integrate over one half of the shell.

since we only integrate over one half of the shell.

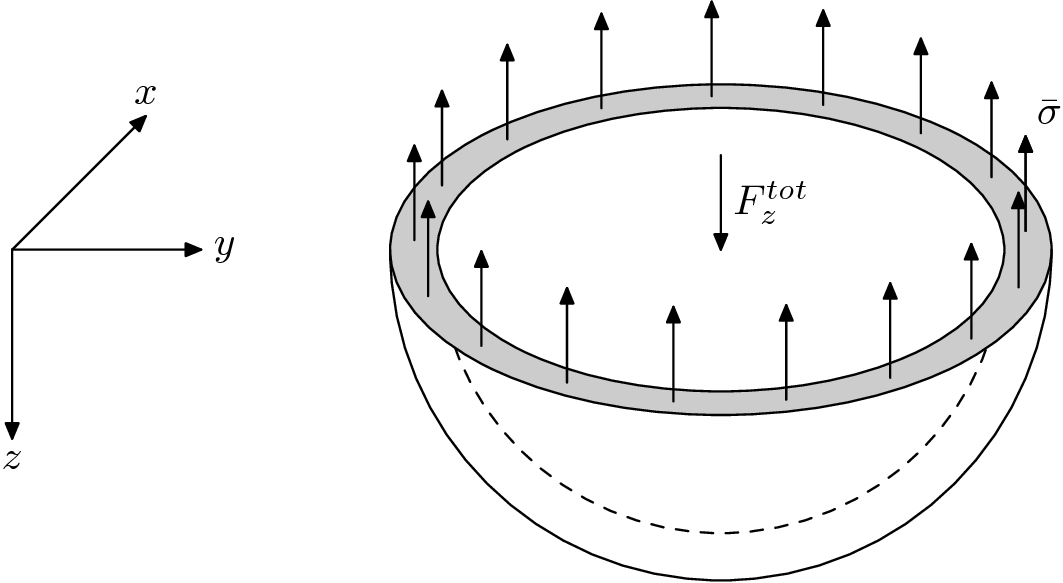

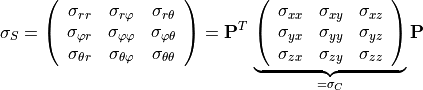

For the derivation of Laplace’s law we approximate the wall stress  by its mean value

by its mean value  ,

see figure Fig. 134. Since the geometry and the acting forces are symmetric, the tangential stress in any

direction must be the same and there will be zero shear stress. Due to the assumption, the mean wall stress at the cut face

just acts just in z-direction, thus we have

,

see figure Fig. 134. Since the geometry and the acting forces are symmetric, the tangential stress in any

direction must be the same and there will be zero shear stress. Due to the assumption, the mean wall stress at the cut face

just acts just in z-direction, thus we have  and

and  .

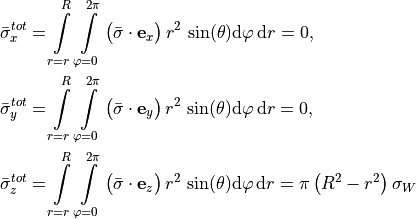

The components of the total wall stress vector

.

The components of the total wall stress vector  are

are

(42)

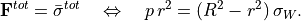

with  . From equations (41) and (42)

we have

. From equations (41) and (42)

we have

(43)

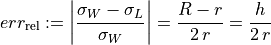

From (43) we conclude that

(44)

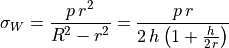

and for  we obtain the law of Laplace

we obtain the law of Laplace

(45)

which can be used to estimate the wall stress for thin walled spherical shells.

Modeling Error

The law of Laplace, see equation (45), is just an approximation to the more accurate formula

(44). The approximation is justified if the wall thickness is mush smaller than the inner

radius. To figure out how strong the relative modeling error depends on  and

and  , we rewrite the

error as

, we rewrite the

error as

(46)

which yields to the condition

if we want to ensure that the relative modeling error is less than  .

.

Example

Assume, that we have a spherical shell with  and we want to use the law of Laplace,

equation (45), to estimate the surface tension. To ensure that the error is

less than one present, that is

and we want to use the law of Laplace,

equation (45), to estimate the surface tension. To ensure that the error is

less than one present, that is  , we have to ensure that the wall thickness

satisfies

, we have to ensure that the wall thickness

satisfies  . For

. For  we have

we have  and

for

and

for  we have

we have  .

.

Verification

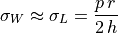

To verify the stress, we first compute the stress tensor  elementwise and project the tensor from the

cartesian coordinate system to the spherical coordinate system, i.e.

elementwise and project the tensor from the

cartesian coordinate system to the spherical coordinate system, i.e.

(47)

with the projection matrix  .

The mean stress tensor then is

.

The mean stress tensor then is

where the integration is applied componentwise.

Experiments

For the experiments we choose the following setups with two different geometries. The first geometry

is a thin walled spherical shell and the second geometry is a rather thick walled spherical shell.

The material model is the Demiray model with  ,

,  and

and  .

.

[mm] [mm] |

[mm] [mm] |

[mm] [mm] |

[kPa] [kPa] |

[ms] [ms] |

|

|---|---|---|---|---|---|

| Experiment 1 | 15.0 | 15.5 | 0.5 | 2.0 | 100.0 |

| Experiment 2 | 15.0 | 15.5 | 0.5 | 4.0 | 100.0 |

| Experiment 3 | 15.0 | 30.0 | 15.0 | 2.0 | 100.0 |

| Experiment 4 | 15.0 | 30.0 | 15.0 | 4.0 | 100.0 |

Using the method described in this section, we obtain the following results.

[kPa]

[kPa] |

[kPa]

[kPa] |

[kPa]

[kPa] |

[kPa]

[kPa] |

[kPa]

[kPa] |

|

|---|---|---|---|---|---|

| Experiment 1 | 39.2682 | 38.7745 | -0.9303 | 38.8500 | 38.8516 |

| Experiment 2 | 83.8585 | 84.8469 | -1.8753 | 83.7231 | 83.7220 |

| Experiment 3 | 0.6937 | 1.0304 | -0.3601 | 0.6260 | 0.6271 |

| Experiment 4 | 1.4428 | 2.1226 | -0.7198 | 1.2951 | 1.2973 |

We see, that for the thin walled geometry the analytically computed wall stress  and

the Laplace approximation

and

the Laplace approximation  are almost equal to the computed mean tangential stresses

are almost equal to the computed mean tangential stresses

and

and  . The radial stress

. The radial stress  is compared to the tangential stresses

negligible. The relative modeling error for the first two experiments are

is compared to the tangential stresses

negligible. The relative modeling error for the first two experiments are  and

and  , see equation (46).

For the experiments with a thick walled geometry we have a rather high discrepancy in the analytical

and computed stresses. The relative modeling errors for the last two experiments are

, see equation (46).

For the experiments with a thick walled geometry we have a rather high discrepancy in the analytical

and computed stresses. The relative modeling errors for the last two experiments are  and

and  .

.

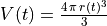

Work Verification

To verify the computed work, we compute the external work analytically and compare it with the computed

internal work. To compute the external work, we use the well known principle of

pressure-volume work

which is  where

where  denotes the volume of the inner sphere

(

denotes the volume of the inner sphere

(  ).

The integral representation then reads

).

The integral representation then reads

(48)

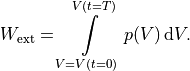

Next, we assume that the pressure is a piecewise linear function of the radius, that is

(49)

for ![r \in [r_{i-1}, r_{i}]](../../_images/math/939f8ccc871caa6cd37c4a853b9b7dfccf07592b.png) and

and  . We get the pressure and radius values

. We get the pressure and radius values  from the

simulation.

from the

simulation.

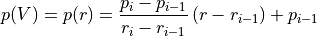

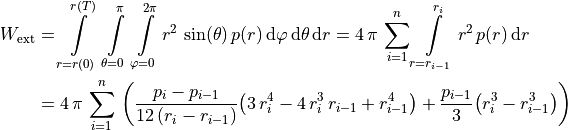

Using spherical coordinates and equation (49), we can write equation (48) as

(50)

which provides an analytical approximation of the external work in [kPa mm^3] = 10^(-6) [J].

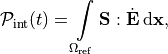

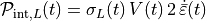

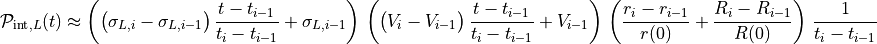

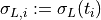

To compute the internal work, we use the internal mechanical power  which is

which is

(51)

see [1] (Section 4.4) for further details. The internal mechanical work  is then given by

is then given by

(52)

Note

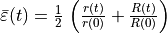

The formula in [3] for the internal heart power and its modification yield

(53)

where  denotes the volume of the geometry at time

denotes the volume of the geometry at time  and

and  denotes

the mean strain rate with the mean strain

denotes

the mean strain rate with the mean strain

.

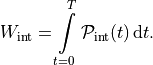

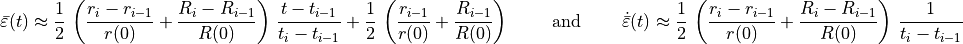

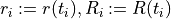

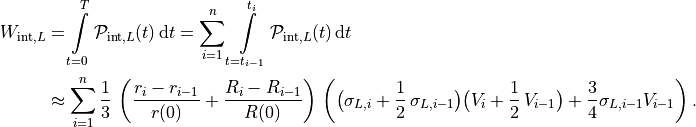

First, we assume that the stress, the volume and the radii depend piecewise linearly on time.

.

First, we assume that the stress, the volume and the radii depend piecewise linearly on time.

For the mean strain we obtain

(54)

with  and

and  . Thus, for

. Thus, for  , we have

, we have

with  and

and  .

.

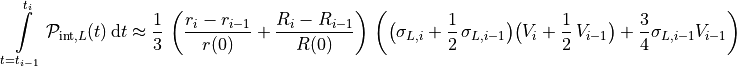

By integrating over  we get

we get

and finally for the internal work  we have

we have

To obtain  we proceed in the same way by replacing

we proceed in the same way by replacing  with

with  .

.

Experiments

Using the same geometrical settings as in Experiments we obtain the following results.

[J]

[J] |

[J]

[J] |

[J]

[J] |

[J]

[J] |

|

|---|---|---|---|---|

| Experiment 1 | 0.00407 | 0.00420 | 0.00434 | 0.00428 |

| Experiment 2 | 0.01072 | 0.01112 | 0.01181 | 0.01167 |

| Experiment 3 | 0.00074 | 0.00070 | 0.00097 | 0.00065 |

| Experiment 4 | 0.00303 | 0.00285 | 0.00396 | 0.00268 |

Meshes

Download the following Python-script and run it!

References

| [1] | Holzapfel, G.A., Nonlinear Solid Mechanics: A Continuum Approach for Engineering (2000), West Sussex, England: John Wiley & Sons, Ltd |

| [2] | Grossman, W. and Jones, D. and McLaurin, L.P., Wall stress and patterns of hypertrophy in the human left ventricle (1975), American Society for Clinical Investigation |

| [3] | Fernandes, J.F. and Goubergrits, L. and Brüning, J. and Hellmeier, F. and Nordmeyer, S. and da Silva, T.F. and Schubert, St. and Berger, F. and Kuehne, T. and Kelm, M. and others, Beyond Pressure Gradients: The Effects of Intervention on Heart Power in Aortic Coarctation (2017), Public Library of Science |

and

and  .

.